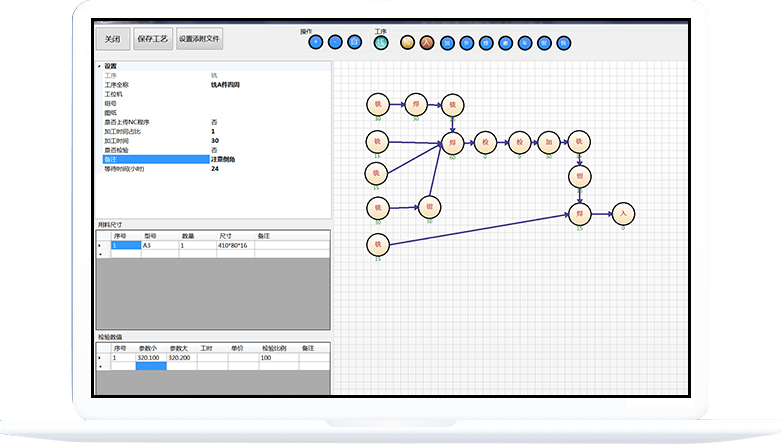

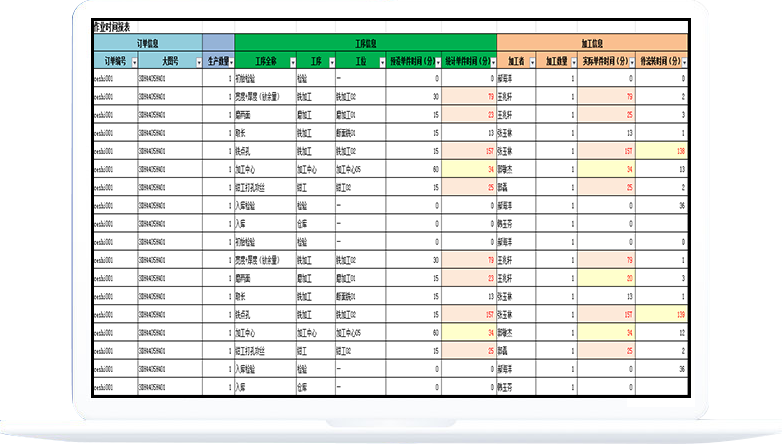

Process and process design

The process design function supports the process design of multi-process parallel combined products (such as assembly, welding, etc.). The "drag-and-drop" process design and modular process parameter input make process layout simple and intuitive, which saves time compared to traditional table format process design.