On April 1, 2021, Wuxi Gongheng Precision Machinery Manufacturing Co., Ltd. (hereinafter referred to as “Gongheng Precision”) and China National Machinery Testing Equipment Co., Ltd. (hereinafter referred to as “SINOTEST”) agreed on the intelligentization of the company’s manufacturing department. Renovation project-the smart manufacturing visualization collaborative cloud platform project was formally signed.

China Machinery Testing Equipment Co., Ltd. (abbreviation: SINOTEST) was founded in 1959, (formerly known as the Minister of Machinery Industry Chun Testing Machine Research Institute, formerly known as Changchun Machinery Science Research Institute Co., Ltd.) is the world's top 500 state-owned enterprises A subsidiary of China National Machinery Industry Corporation, it is the supporting unit of the National Testing Machine Quality Supervision and Inspection Center and the National Testing Machine Standardization Committee. The National Testing Machine Industry Association and the Association Secretariat are both located in China Machine Testing, known as "China Testing Machine Technology" cradle".

SINOTEST is a Chinese engineering test equipment and material test solution provider, and a high-tech enterprise with perfect innovation capabilities in China's test equipment industry. Gongheng Precision organized a technical team to go to the Changchun headquarters in Jilin Province for many in-depth investigations and diagnoses. With the goal of improving production efficiency, saving labor costs, and improving quality and efficiency as the starting point, the intelligent manufacturing visualization collaborative cloud was tailored for SINOTEST. platform.

The platform covers functions such as order management, process design, process control, visualized real-time monitoring, data accumulation, intelligent scheduling, etc., and realizes the intelligent scheduling plan and delivery date of the commissioning orders in real time. It can be scheduled and dynamic. Optimize workshop operations and realize the dynamic optimization scheduling ability of rapid response to abnormal events and automatic recovery. The platform is equipped with online detection and alarm functions. When necessary, one-key call detection can be used to truly realize the whole process monitoring and traceability of human, machine, material, method, and environmental production operations.

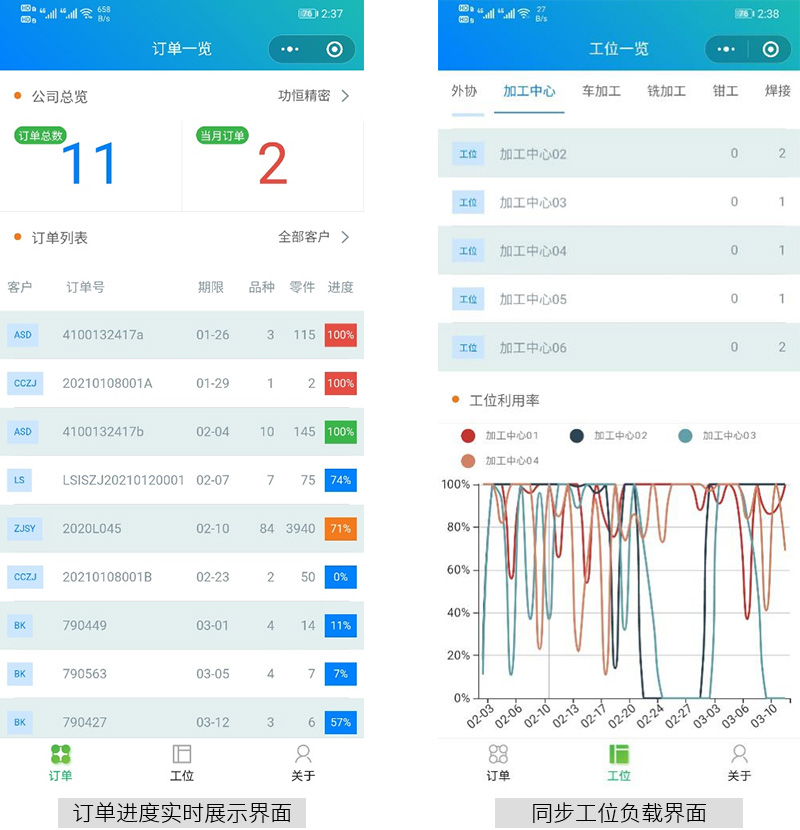

Visual Kanban interface

At the same time, in order to facilitate enterprise management to understand real-time order status, production progress, station load, etc., we independently developed and launched the "Gongheng Zhizhi" WeChat applet to realize real-time online viewing on the mobile terminal, which is convenient and efficient.

The successful signing of the project is not only an important step taken by Sinotest in the intelligent transformation of Changchun, Jilin, but also means that Changchun City has a new model and model for intelligent transformation.

It is hoped that SINOTEST will rely on the first-mover advantage of this intelligent transformation to give full play to the high-level support service role of central enterprises, and play a demonstrative role in promoting the transformation and upgrading of intelligent manufacturing in the field of test equipment, high-end equipment manufacturing industry and even traditional manufacturing.

Wuxi Gongheng Precision Machinery Manufacturing Co., Ltd. was established in 2014. It is a comprehensive service provider integrating high-end customized machining services, "intelligent visualization collaborative cloud platform" products with completely independent intellectual property rights, and customized services and solutions. As an "amphibious" technological innovation enterprise integrating manufacturing and software intelligent manufacturing, the company adheres to the goal of assisting discrete non-standard intelligent manufacturing enterprises with digital production, creating value for customers and creating value for partners, and helping production enterprises achieve digitalization, Paperless production reduces corporate management costs and enhances workshop production collaboration efficiency. Gongheng Precision takes its own actual needs as the fundamental driving force, and through continuous hard work, it has become a high-quality partner for many domestic enterprise-level customers.